HI-520-0320 Dual-Channel Process Controller

In Stock 2 Items available

HI-520-0320

HI-520 is an advanced process controller that can be configured for applications requiring monitoring and/or control of five main water-analysis parameters: pH, ORP, Conductivity, Turbidity and Dissolved Oxygen. Speak with our experts here at Hanna.

For use in any process application including effluent plants (wastewater), also in manufacturing, or using water or chemicals; food, plating, paper, plastics, car components and many other industries. Speak with our experts here at Hanna.

About the HI-520 series Dual-Channel Universal Process Controllers

- Waterproof IP65 (NEMA 4X) enclosure

- Large backlit LCD

- Multi-colour LED status indicators

- Audible alarm

- Tactile rubberised keypad

- Universal mounting

- Universal Hanna digital probe

About the HI-520-0320

This controller has 3 relays and 2 analogue inputs supplied with 3 metre power cable, cable gland set, instrument certificate and quick reference guide with instructions for product manual download.

Also available:

HI-520-0540 5 relays and 4 analogue inputs supplied with 3 metre power cable, cable gland set, instrument certificate and quick reference guide with instructions for product manual download.

General overview of the HI-520 series

The controller features a digital probe input(s) that automatically detects and updates the controller with the parameter that it is measuring.

HI-520 is Hanna's first dual-input process controller that accepts virtually any combination of compatible probes.

Designed to adapt to unique process control requirements, users have the option to enable or disable each channel independently.

Additionally, HI-520 introduces enhanced industrial control by operating a control-loop system whereby users have the option to run channel control either independently or configure to be triggered sequentially upon reaching the other channel's set point(s) (1, 2, or both). The device operates a logical channel with built-in mathematical functions.

This function is intended for when the controller works as an analyser for monitoring high/low parameter levels between two identical inputs with identical measuring configurations.

The Universal Process Controller offer wall, pipe, and panel mounting options and feature a large backlit dot matrix display for easy viewing and provide an intuitive interface for setup options.

The controllers utilise multi-colour LEDs for easy viewing of the instrument’s status including relay activation, in alarm mode, or in hold status. All programming operations are done through the low profile vulcanised rubber keypad or with an RS485 connection to a supervisory computer.

Features Displayed on Screen – all models

Control Modes

The control mode can be configured to be On/Off, Proportional, or PID.

The mode can be set high or low. High control mode is required if the process value is too high and needs to be decreased. Low control mode is required if the process value is too low and needs to be increased.

For On/Off control, the hysteresis band is adjustable, while in Proportional and PID modes, deviation, control period, and other tuning parameters can be set to optimise control around a set point.

For HI-520, each channel can run control independently or sequentially.

Hold Function

During calibration, cleaning, and configuration the controller automatically goes into Hold mode. During Hold mode all control loops related are disabled. The analogue outputs may be configured to go to a fixed value or remain at the last value.

The Hold function can also be triggered manually, using an external digital input or by entering in Manual mode. This is useful for disabling control when performing maintenance.

Auto-Cleaning Cycle

Difficult applications often require an almost continuous maintenance of the probe. Processes with high-suspended solids, fats, oils, pigments, and micro-organisms will coat the pH sensing glass, ORP sensors, and the reference junction. The cleaning function allows programming of one or more wash cycles and uses the relays to activate valves, pumps or compressed air based on the type of washing that is required to maintain probes for reliable results.

Configurable Alarm System

The alarm system is configurable for measured parameters. The alarm can also be activated by event triggers or abnormal operation. For example, if a dosing relay remains closed for an excessive period of time or if temperature exceeds an upper limit during an exothermic neutralisation reaction. A blinking red LED signals an alarm state.

All relays configured for control are inactivated until the alarm state is resolved.

On HI-520 use channel configuration to setup and trigger an alarm.

LCD Information

Local visual indicators of measurement details as well as errors are displayed. The ? DIAG key provides details of the issue.

? DIAG - Help and Diagnostic Key

The help and diagnostic key (? DIAG) provides information related to errors; or in setup mode, information about settings.

Digital Inputs

- Two digital inputs for remotely triggering, cleaning and hold functions

Analog Outputs

- Up to 4 analogue outputs and 5 relays used for control and for sending a signal to data loggers, PLC, SCADA and other remote monitoring systems

- 0-20 mA or 4-20 mA

- Scalable in selecting values for the range

- Can be used for control of pumps and valves

- On alarm state can output a 22 mA signal to the monitoring system

Digital Communication

- The Modbus-compliant unit can be integrated within a Modbus-based network and connected to other industrial electronic devices. The following tasks may be accomplished remotely:

- Monitoring, using the virtual LCD (limited to a single remote control in the entire network)

- Setup

- Loading the Setup configuration file to a controller

- RS485 Digital output for PC and other device connectivity

Relays

- Up to 5 control and 1 alarm electromechanical relays

- Replaceable 5A fuses to protect all relays

- Extractable terminal blocks for easy wiring

- Relay options include single pole double throw (SPDT) and single pole single throw (SPST)

- Control relays can be programmed for On/Off, Proportional, or PID control as well as Cleaning and Hold functions

- Configurable alarm relay

- Relays terminal blocks and their wires paths are separated from the low voltage section for additional safety

Automatic Data-logging

HI-520 have built-in data logging that stores data at selectable intervals along with relay control settings and calibration data.

- Data stored in up to 100 lots with each holding 8600 records

- Selectable log interval: from 10 seconds to 3 hours

- Logged Data includes: Measured values and alarms for all supported parameters; Calibration information including solutions used. For pH, the offset and slope is recorded.

Event Log

The Event Log file can hold a maximum of 100 events. It includes errors, alarms, warnings, calibration events, configuration changes, and cleaning events.

Password protection

The controllers feature password protected calibration and setup.

NEMA 4X Enclosure

The controllers are suitable for indoor or outdoor environments. The NEMA 4X enclosure ensures the electronics are protected against splashing and hose-directed water or windblown dirt, dust, rain or sleet. It also provides corrosion protection for use near salt water.

Cable Glands

To maintain the NEMA 4X enclosure rating during use, the conduit openings and connection cables are sealed against the environment using the provided cable glands, seals, and plugs.

Spring Loaded Screws

The front panel is hinged at the front of the enclosure for easy access to wiring locations. It features spring loaded screws that won’t fall out when accessed.

USB Type-C Port

Logged data can be transferred to a flash drive as a .csv file using the USB Type-C port. A rubberised plug helps protect the port against the ingress of water.

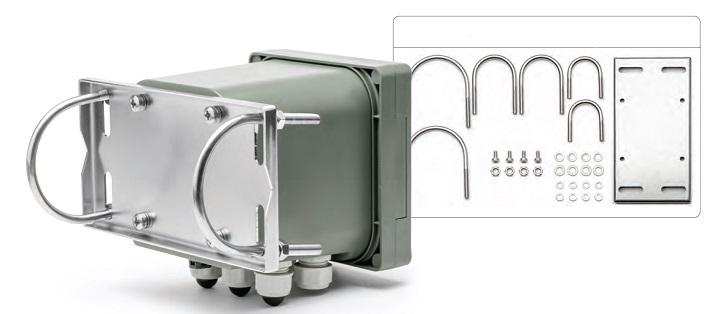

Installation options

The controllers can be securely panel mounted through a half-inch DIN opening using the HI510-01 Panel-Mount Kit. The kit includes a sealing gasket, dual zinc coated brackets, and associated hardware.

The controllers can be surface mounted using the HI-510-02 Wall-Mount Kit. The kit includes a zinc coated mounting plate and associated hardware. The plate may be oriented vertically or horizontally.

The controller can be mounted to a vertical or horizontal pipe using the HI-510-03 Pipe-Mount Kit. The kit includes a zinc coated mounting plate, associated hardware, and U-bolts to accommodate a 1 inch, 1-and-a-half inch, or 2 inch pipe.

Compatible Electrodes

HI-1006 and HI-1016

HI-1006 and HI-1016 pH and Temperature Industrial Smart Probes are intended for industrial process control. With an internal temperature sensor, flat tip, and PVDF body these probes are suitable for continuous measurement of pH in applications like wastewater treatment, industrial effluent treatment, and surface water monitoring.

These probes can be installed in-line, immersed in a tank, or installed into a flow cell.

HI-1026-1803

HI-1026-1803 pH and Temperature Industrial Smart Probe for Meat Applications are designed to ensure consistent and safe meat product measurement that comply with food safety regulations. It is ideal for the meat processing industry including abattoirs, meat processing, and butchers. It is also compatible with a 49 mm (2") stainless steel blade tip that is rustproof, corrosion resistant and functions to protect the pH glass and pierce into a meat sample.

HI-1126-1805

The HI-1126-1805 Industrial Smart Probe for Food Applications is designed as a versatile general purpose electrode. It sports a sturdy, chemically resistant PP body with a conical tip probe that can be used in most food applications. The probe manages temperature compensation and buffer calibration settings.

HI-2004 and HI-2014

HI-2004 and HI-2014 are designed to monitor and control disinfection chemicals or follow and control a critical oxidation (or reduction). mV measurements are auto- compensated.

The PTFE junction is ideal for samples with high content of suspended solids or for high pressure installations, while the ceramic junction is porous and chemically resistant making it ideal to handle more general applications.

HI-7630-28

The HI-7630-28 is a dual electrode probe that is ideal for testing in pure and ultra-pure water. It is recommended to be calibrated with a standard value that is close to the measurement value.

This probe can be installed directly in-line, immersed in a tank, or installed into a flow cell. It is suited for continuous measurement of conductivity, TDS, or resistivity required commonly in water treatment, feed water condensate, and drinking water. It is also capable of working in applications needing sea water or sur face water monitoring.

The internal temperature sensor measures process temperature and adjusts the measured conductivity to a reference temperature by applying specialised compensation standards: Linear, Standard, and Natural.

HI-7630-48

The HI-7630-48 is a four-ring probe that is ideal for general applications such as industrial process water. It offers stable measurements over a wide range and does not require frequent calibration.

This probe can be installed directly in-line, immersed in a tank, or installed into a flow cell. It is suited for continuous measurement of conductivity, TDS, or resistivity required commonly in water treatment, feed water condensate, and drinking water. It is also capable of working in applications needing sea water or surface water monitoring.

The internal temperature sensor measures process temperature and adjusts the measured conductivity to a reference temperature by applying specialised compensation standards: Linear, Standard, and Natural.

HI-7640-18

The HI-7640-18 is the galvanic dissolved oxygen option compatible with the HI-520. It is suitable for control applications in municipal and industrial wastewater treatment. The probe can be submersed/ immersed using the ¾ inch NPT threads, installed directly in-line, or in a flow cell.

This probe has a larger electrolyte reservoir to provide a longer service life, though the caps and electrolyte will still need replacement. This probe has a 3 bar (43.5 psi) maximum pressure.

HI-7640-58

The HI-7640-58 is Hanna's first optical dissolved oxygen option for process instrumentation.

When paired with the controller, the system provides accurate dissolved oxygen measurements auto- compensated for barometric pressure, salinity (set manually), and temperature.

The probe is designed for control applications in aeration basins, ponds, and tanks where optimising oxygen transfer is a key element.

The probe can be submersed/immersed in a tank using the ¾ inch NPT threads, or installed in a flow cell using the lower threads.

The optical probe requires a replacement membrane cap only once a year and it does not use electrolyte. Detecting oxygen does not require the consumption of oxygen to take place like in that of polarographic or galvanic dissolved oxygen probes.

HI-7660 Low Range Turbidity Probe

The HI-7660-28 is a nephelometric turbidity probe designed for use with Hanna Instruments’ HI-510 or HI-520 Universal Process Controllers.

The probe is designed to measure low turbidity values according to the nephelometric method (ISO 7027 – EN 27027).

An integral temperature sensor measures water temperature and adjusts the probe signal for temperature-related changes over the range of 0 to 50°C.

Turbidity is a key indicator of water quality and effectiveness of water filtration.

The system is suitable for applications in drinking water, municipal and industrial water treatment, desalination and water quality monitoring.

Read More

| Channels | 2 | |

| Display | Graphic LCD, 128 x 64 pixel B/W with backlight | |

| Digital Inputs | 2 independent, galvanically isolated inputs (configurable for Hold & Cleaning functions); On state: 5 to 24 Vdc, low or high level active | |

| Analogue Outputs | 2 or 4 independent, galvanically isolated outputs 0 – 22 mA configurable as: 0 – 20 mA; 4 – 20 mA 22 mA as alarm signal, configurable option | |

| Analog Output Accuracy | ±0.2% f.s. | |

| Digital Communication | RS485 serial port - Remote monitoring and control USB-C port - Retrieve log files and firmware upgrading | |

| Relays | Up to 5 relays (independently configurable for process variables, Hold & Cleaning functions) Electromechanical relay SPDT and SPST contact outputs 5A – 250 Vac; 5A – 30 Vdc (resistive load) Fuse protected: 5A, 250V slow blow fuse | |

| Alarm Relay for All Measurement Alarms | Electromechanical relay SPDT contact output 5A – 250 Vac; 5A – 30 Vdc (resistive load) Fuse protected: 5A, 250V slow blow fuse | |

| Data Logging | Interval log, up to 100 files, maximum 8600 records on each stored file. When the maximum limit of 100 stored files is reached, the most recent file will automatically erase the oldest one. Event log, maximum 100 records. When the maximum limit is reached, the last record overwrites the oldest one. | |

| Power Supply | 100 – 240 Vac ±10%; 50/60 Hz; 15VA; fuse protected (2A, 250V slow blow fuse) | |

| Power Consumption | 15 VA | |

| Installation Category | II | |

| Environment | -20 to 50 ºC (-4 to 122 ºF); maximum 100% RH non-condensing | |

| Enclosure* | Single case ½ DIN, type 4X, IP65 ingress protection | |

| Weight | Approximately 1.6 kg (3.5 lb.) | |

| Dimensions | Width: 144.0 mm (5.7”); Height: 144.0 mm (5.7”); Depth: 151.3 mm (6.0”) | |

| Ordering Information | HI-520-0320 universal process controller with 3 relays and 2 analogue outputs is supplied with 3m power cable, cable gland set, instrument certificate, and quick reference guide with instructions for manual download. HI-520-0540 universal process controller with 5 relays and 4 analogue outputs is supplied with 3m power cable, cable gland set, instrument certificate, and quick reference guide with instructions for manual download. | |

| Accessories | HI-510-01 panel-mount kit HI-510-02 wall-mount kit HI-510-03 pipe-mount kit HI-76510-10 patch cable, 10 m (32’9”) HI-76510 -15 patch cable, 15 m (49’2”) HI-76510-25 patch cable, 25 m (82’) HI-76510-05 patch cable, 5 m (16’5”) HI-76510-50 patch cable, 50 m (164’) | |

| * | For a water tight seal: Gland seals need to be used over cables and the four screws on the front casing need to be tightened to 13.3 lbf·in (1.5 N·m, maximum 2.0 N·m), of torque |