+44 (0)1525 850 855

Order before 4pm for same day dispatch

Weekdays only

Menu

-

MenuBack

-

Home

-

-

By product type

- Benchtop Meters

- Chemical Dosing Pumps

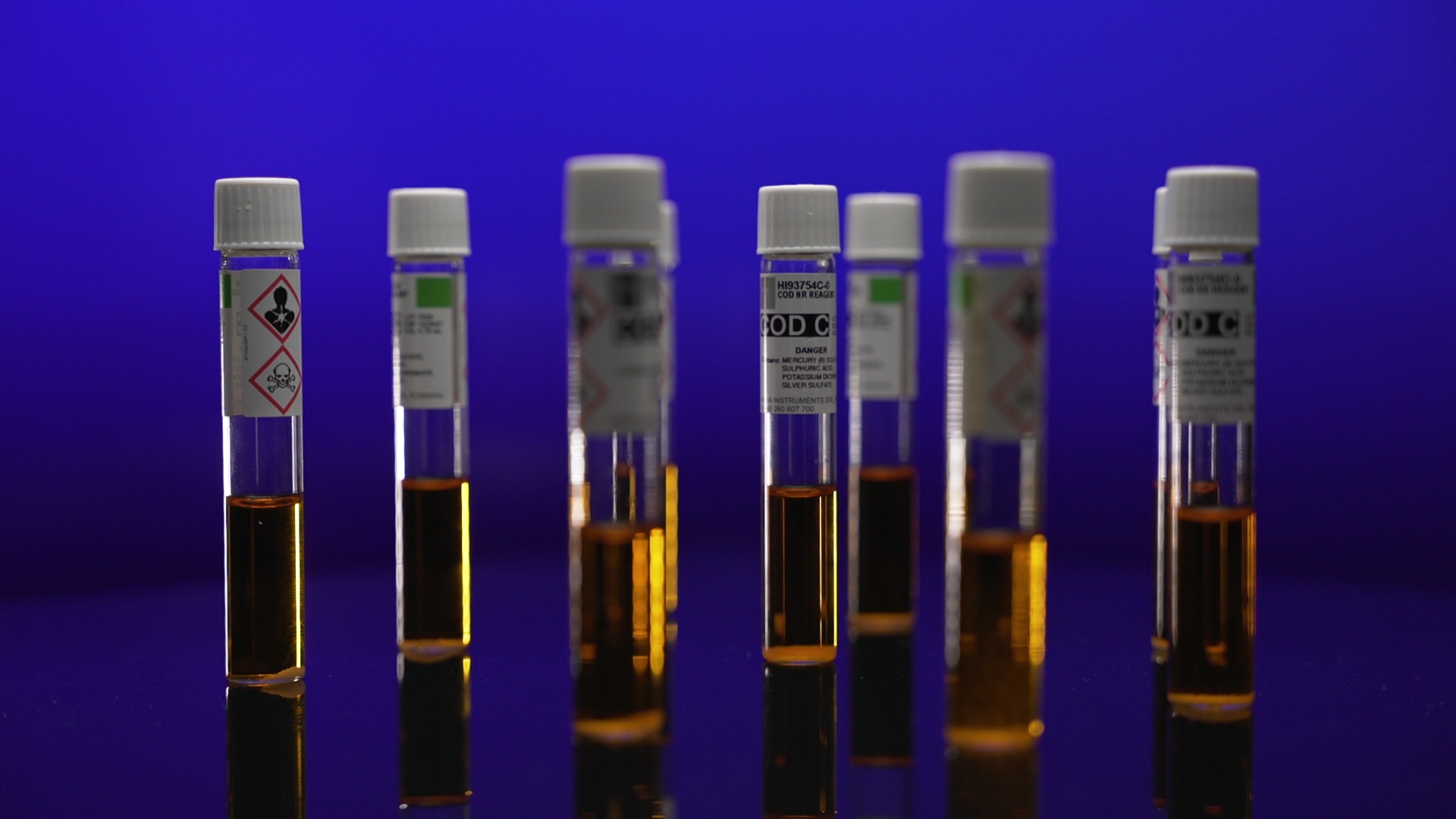

- Chemical Oxygen Demand (COD) Meters

- Chemical Test Kits

- Conductivity Meters

- Controllers & monitors - pH & multiparameter

- Dissolved Oxygen Meters

- Magnetic Stirrers

- pH Meters

- Photometers

- Spectrophotometers

- Thermometers

- Titrators

- Total Dissolved Solids Meters (TDS)

- Turbidity Meters

- Refractometers

- ORP Meters

- Other Accessories and Spares

- Conductivity Electrodes

- Dissolved Oxygen Probes

- Ion Selective Electrodes (ISE)

- ORP Electrodes

- pH Electrodes

- Thermometer Probes

- Titration Electrodes

- Total Dissolved Solid Probes (TDS)

- Turbidity Electrodes

- Chemical Oxygen Demand (COD) solutions

- Conductivity Solutions

- Dissolved Oxygen Solutions

- Food and Drink Care Solutions

- Groline Solutions for Agriculture

- Ion Selective Measurement Solutions

- ORP Solutions

- pH Solutions

- Photometer solutions

- Pool, Spa & Hot Tubs Solutions

- Refractometer Solutions

- Titration Solutions

- Total Dissolved Solids Solutions (TDS)

- Turbidity Solutions

- Acidity

- Alkalinity

- Aluminium

- Ammonia

- Ascorbic Acid

- Bromine

- Calcium

- Carbon Dioxide

- Chloride

- Chlorine Dioxide

- Chlorine

- Chromium

- Copper

- Cyanide

- Cyanuric Acid

- Dissolved Oxygen

- Fluoride

- Formaldehyde

Meters

Electrodes and Probes

Solutions

Reagents

-

-

-

By Parameters

- Chemical Oxygen Demand

- Conductivity

- pH

- Salinity

- Dissolved Oxygen

- Temperature

- Total Dissolved Solids

- Turbidity

- Multi Parameter Devices

- Acidity

- Alkalinity

- Ammonia

- Aluminium

- Ammonium

- Anionic Surfactants

- Ascorbic Acid

- Boron

- Bromide

- Bromine

- Cadmium

- Calcium

- Carbon Dioxide

- Chloride

- Chlorine

- Chlorine Dioxide

- Colour

- Chromium

- Copper

- Cyanide

- Cyanuric Acid

- Fluoride

- Formaldehyde

- Glycol

- Hardness

- Hydrazine

- Hydrochloric Acid

- Hydrogen Peroxide

- Hypochlorite

- Iodide

- Iodine

- Iron

- Lead

- Magnesium

- Manganese

- Molybdenum

Main Parameters

Individual Parameters

-

-

-

-

-

-

-

-

-

-

-

By product type

- Back

-

Meters

- Back

- Benchtop Meters

- Chemical Dosing Pumps

- Chemical Oxygen Demand (COD) Meters

- Chemical Test Kits

- Conductivity Meters

- Controllers & monitors - pH & multiparameter

- Dissolved Oxygen Meters

- Magnetic Stirrers

- pH Meters

- Photometers

- Spectrophotometers

- Thermometers

- Titrators

- Total Dissolved Solids Meters (TDS)

- Turbidity Meters

- Refractometers

- ORP Meters

- Other Accessories and Spares

- pH accessories and spares

- Photometer and Turbidity accessories

- Thermometers accessories and spares

- Electrodes and Probes

-

Solutions

- Back

- Chemical Oxygen Demand (COD) solutions

- Conductivity Solutions

- Dissolved Oxygen Solutions

- Food and Drink Care Solutions

- Groline Solutions for Agriculture

- Ion Selective Measurement Solutions

- ORP Solutions

- pH Solutions

- Photometer solutions

- Pool, Spa & Hot Tubs Solutions

- Refractometer Solutions

- Titration Solutions

- Total Dissolved Solids Solutions (TDS)

- Turbidity Solutions

-

Reagents

- Back

- Acidity

- Alkalinity

- Aluminium

- Ammonia

- Ascorbic Acid

- Bromine

- Calcium

- Carbon Dioxide

- Chloride

- Chlorine Dioxide

- Chlorine

- Chromium

- Copper

- Cyanide

- Cyanuric Acid

- Dissolved Oxygen

- Fluoride

- Formaldehyde

- Glycol

- Hardness, Calcium

- Hardness, Magnesium

- Hydrazine

- Hydrogen Peroxide

- HypoChlorite

- Iodine

- Iron

- Lead

- Magnesium

- Manganese

- Molybdenum

- Nickel

- Nitrate

- Nitric Acid

- Nitrite

- Nitrogen

- Ozone

- Peroxide

- pH

- Phenols

- Phosphate

- Phosphorus

- Potassium

- Salinity

- Silica

- Silver

- Sodium Chloride

- Sodium Hydroxide

- Sulphate

- Sulphite

- Sulphuric Acid

- Surfactants, Anionic, Cationic, Nonionic

- Zinc

-

By Parameters

- Back

- Main Parameters

-

Individual Parameters

- Back

- Acidity

- Alkalinity

- Ammonia

- Aluminium

- Ammonium

- Anionic Surfactants

- Ascorbic Acid

- Boron

- Bromide

- Bromine

- Cadmium

- Calcium

- Carbon Dioxide

- Chloride

- Chlorine

- Chlorine Dioxide

- Colour

- Chromium

- Copper

- Cyanide

- Cyanuric Acid

- Fluoride

- Formaldehyde

- Glycol

- Hardness

- Hydrazine

- Hydrochloric Acid

- Hydrogen Peroxide

- Hypochlorite

- Iodide

- Iodine

- Iron

- Lead

- Magnesium

- Manganese

- Molybdenum

- Nickel

- Nitrate

- Nitrite

- Nitrogen

- ORP

- Oxygen

- Ozone

- Peroxide Value

- Phenols

- Phosphate

- Phosphorus

- Potassium

- Potassium Chloride

- Salinity

- Silica

- Silver

- Sodium

- Sodium chloride

- Sugars & Brix

- Sulphate

- Sulphide

- Sulphite

- Sulphur Dioxide

- Tartaric Acid

- Zinc

- Agriculture

- AQUARIUM

- FOOD

- LABORATORY

- POOLS, SPAS & HOT TUBS

- WATER

- Contact Us

- KNOWLEDGE HUB